Infrared & Corona

RotorWorks has performed Infared and Corona inspections for the Power Industry since 2000. Our personnel receive initial and recurrent training to provide our customers with the highest quality deliverable. Our aerial solutions provide reliability and efficiency for your Transmission Infrastructure. The ability to easily detect corona and arcing sources and pinpoint their locations can save utility companies considerable money. Aerial UV scans, when coupled with an aerial platform, increases the reliability of our customers’ systems. You can now access areas that could not normally be inspected by ground methods, thus allowing for better preventative maintenance, less downtime, and increased reliability. The information collected allows managers to schedule maintenance and avoid electrical components failures as well as unforeseen safety issues.

Infrared (IR)

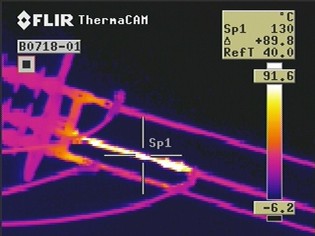

Thermal imaging, also called thermography, is the production of non-contact infrared or “heat” pictures from which temperature measurements can be made. Portable infrared cameras scan equipment and structures, then instantly convert the thermal images into pictures in a JPEG format for monitoring and analysis. Thermal imaging increases efficiency and maximizes safety in many industries and environments and is rapidly expanding into new markets.

Aerial infrared surveillance is performed by the use of a gyro stabilized system with the combination of the following equipment: FLIR ThermaCAM SC3000 (infrared camera), digital and broadcast quality video camera. The ThermaCAM SC 3000 QWIP sensor, the most advanced detector technology available, provides superior image resolution of 320 x 240 pixels. This camera utilizes an advanced Quantum Well Infrared Photodetector FPA sensor that provides extremely high sensitivity of less than 20 mK at 30 °C, ideal for applications requiring ultra-precise measurement accuracy.

Infrared Reporting

Each line comes with:

Standard

1. IR and Visual videos on CD/DVD/Portable HD

2. Thermal reports of “Hot” components delivered to customer in hard copy and .pdf formats

3. Documentation of line problems

Optional

1. Raw IR Image

2. IR and Visual Comparison Report

3. Data Analysis

4. Complete IR Report (.pdf format)

All are documented with date, time and GPS coordinates.

Aerial infrared surveillance is performed by the use of a gyro stabilized system with the combination of the following equipment: FLIR ThermaCAM SC3000 (infrared camera), digital and broadcast quality video camera. The ThermaCAM SC 3000 QWIP sensor, the most advanced detector technology available, provides superior image resolution of 320 x 240 pixels. This camera utilizes an advanced Quantum Well Infrared Photodetector FPA sensor that provides extremely high sensitivity of less than 20 mK at 30 °C, ideal for applications requiring ultra-precise measurement accuracy.

Infrared Reporting

Each line comes with:

Standard

1. IR and Visual videos on CD/DVD/Portable HD

2. Thermal reports of “Hot” components delivered to customer in hard copy and .pdf formats

3. Documentation of line problems

Optional

1. Raw IR Image

2. IR and Visual Comparison Report

3. Data Analysis

4. Complete IR Report (.pdf format)

All are documented with date, time and GPS coordinates.

Corona (UV)

Corona occurs when the air in the vicinity of a conductor or on any piece of electrical component is ionized due to a high electrical field thereby creating CORONA and or ARCING.

CORONA-activity creates corrosive substances, like nitrogen oxides and ozone. These degrade the polymer housing and any electrical component. This allows moisture and acid to penetrate the fiberglass rod, leading to insulator or component failure. A fault on a polymer insulator usually progresses rapidly and may lead to line failure.

The ability to easily detect corona and arcing sources and pinpoint their locations can save utility companies considerable money. Aerial UV scans, when coupled with an aerial platform, increases the reliability of our customers’ systems. You can now access areas that could not normally be inspected by ground methods, thus allowing for better preventative maintenance, less downtime, and increased reliability. The information collected allows managers to schedule maintenance and avoid electrical components failures as well as unforeseen safety issues.

CORONA-activity creates corrosive substances, like nitrogen oxides and ozone. These degrade the polymer housing and any electrical component. This allows moisture and acid to penetrate the fiberglass rod, leading to insulator or component failure. A fault on a polymer insulator usually progresses rapidly and may lead to line failure.

The ability to easily detect corona and arcing sources and pinpoint their locations can save utility companies considerable money. Aerial UV scans, when coupled with an aerial platform, increases the reliability of our customers’ systems. You can now access areas that could not normally be inspected by ground methods, thus allowing for better preventative maintenance, less downtime, and increased reliability. The information collected allows managers to schedule maintenance and avoid electrical components failures as well as unforeseen safety issues.